LOADING DOCK EQUIPMENT

EDGE OF DOCK LEVELERS & EQUIPMENT

DLM is your one-stop-shop for complete loading dock solutions. While Edge-of-Docks from DLM are most common, products also include pit-style levelers, vehicle restraints, dock communication, accessories, and more. All DLM products are proudly Made in the USA.

DLM PRODUCTS

-

LOADING DOCK

VIEW PRODUCTS

LEVELERS -

iDOCK CONTROLS

VIEW PRODUCTS -

VEHICLE

VIEW PRODUCTS

RESTRAINTS -

EDGE-OF-DOCK LEVELERS

VIEW PRODUCTS -

SAFETY

VIEW PRODUCTS

PRODUCTS -

DOCK ACCESSORIES

VIEW PRODUCTS

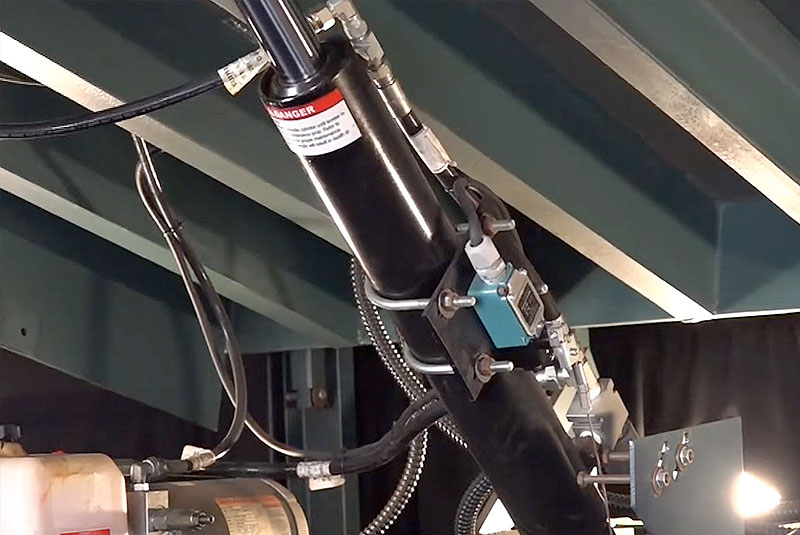

STRENGTH AND DURABILITY

DLM equipment has proven the test of time with its strong and durable design. From the use of structural steel in dock levelers, to the mechanics of vehicle restraints, all DLM products are built to last.

MADE IN THE USA

With facilities in Wisconsin and Arkansas, DLM is proud to manufacture all of its products in the USA.

INSTALLATIONS GALLERY

Not sure what’s possible when partnering with DLM? Let this page be your inspiration.

View GalleryINSTALLATIONS GALLERY

Not sure what’s possible when partnering with DLM? Let this page be your inspiration.

View Gallery